Quality characteristics

Omniseal-Solutions® semi-finished PI-s products are manufactured using compression molding (CM) or direct forming (DF) processes. The semi-finished parts produced using CM process have relatively higher mechanical properties due to higher level of PI-s powder compaction. In line with different requirements of the Industrial market, Meldin® product family can provide:

- High temperature resistance intermittently up to 482°C

- Continuous use temperature up to 315°C

- Excellent chemical resistance

- Excellent dimensional stability at elevated temperatures

- 100% PFAS free

In line with different requirements of the industrial market, the PLAVIS ‘S’ product family can provide:

- A high temperature resistance with continuous operating temparature up to 350°C and a lower coefficient of thermal expansion than the traditional thermosetting polyimides.

- Wide thermal resistance, even at temperatures over 350°C the tensile strength reduction does not occur for a long period, which also facilitates wear resistance and long lasting properties

- Low coefficient of thermal expansion, lighter weight and more dimensional stability than the traditional Polyimide material

Applications

Semi finished Polyimide parts from Omniseal-Solutions® are machined to finished parts which are then used in various applications in the

- Automotive industry

- Thrust washer or piston rings in transmission and pumps replacing tradional metals

- Aero space industry

- Jet engine parts such as pads, bumpers, seals and bearings

- Industrial machinery

- Thermal insulators for hot runner nozzles used for injectionn molding of thermoplastic products such as PET-preforms

- Electronic industry

- CMP Rings

- HDPCVD equipment

- Drie equipment

- ETCH application

- Sputtering equipment

- End wafer transfer robot

- IC testing

- Dry etcher

The semi-finished shapes and finished parts from PLAVIS 'S' material are used in a wide range of industrial applications

- Aerospace

- Jet engine parts in engine applications, wear pads and strips, thrust washers, bushings, bearings, bumpers, linkage components and door mechanisms.

- General industry

- Seal caps, glass bottle grippers, valve components, vehicle transmission ball valves and replacing metal bearing

- For Semiconductor & Insulators

- Wafer Clamp Rings, Insulators requiring dielectric properties, Screws & Fasteners, Vacuum Pads, Alignment Pins, Wafer Guides, Wafer Carriers, insulator clamp inserts or seals and valve seats

We offer

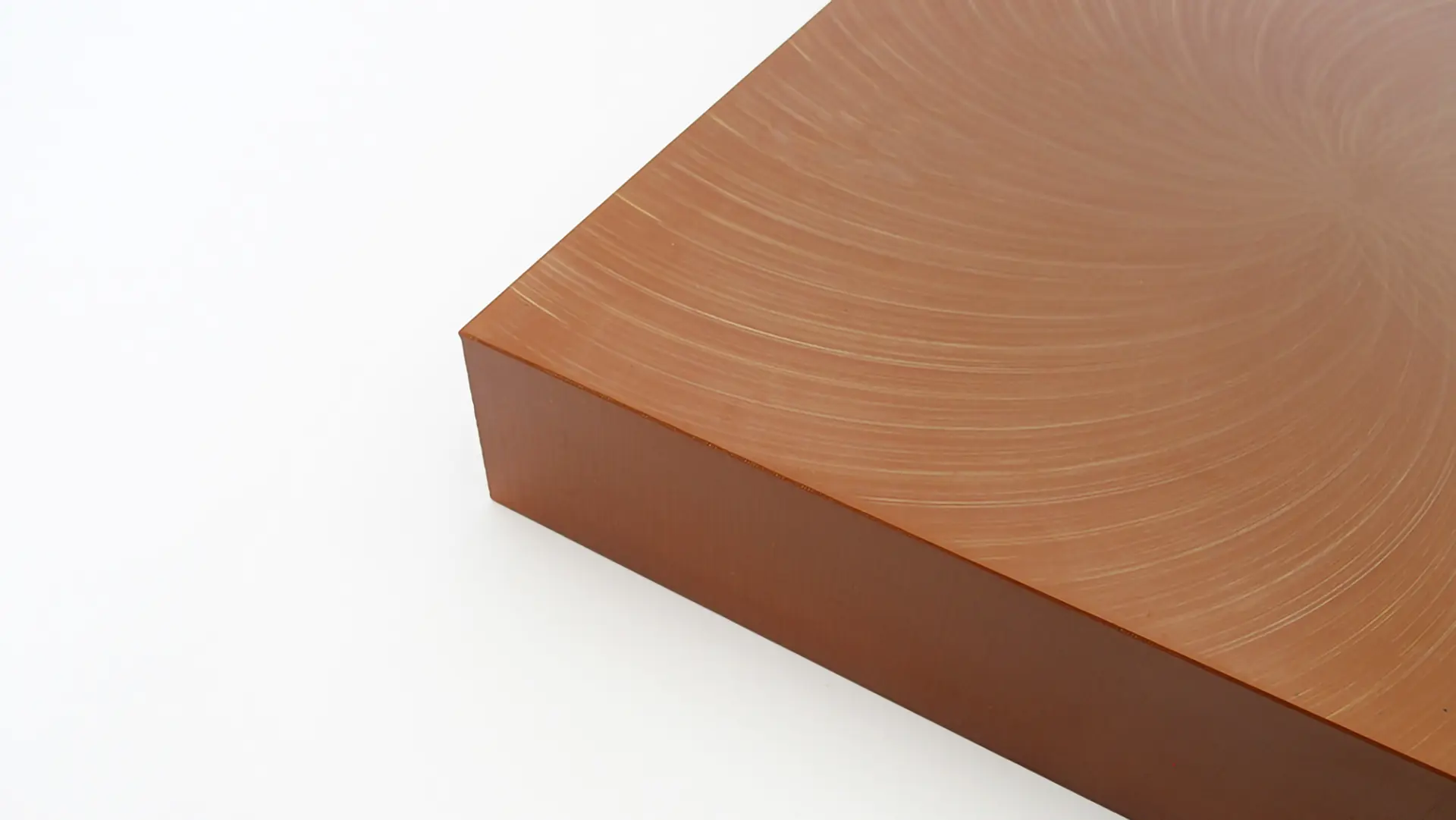

POLYIMIDE Sheets of Saint-Gobain

Polyimide-Sheets are available at 305 x305mm width and length and with minimum thickness of 1.6mm up to maximum thickness of 50,8mm

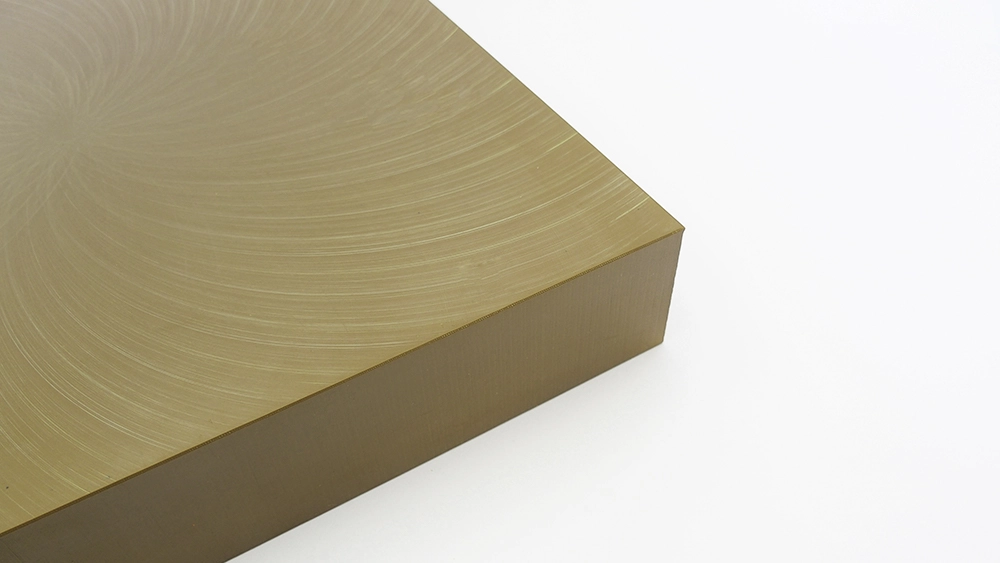

POLYIMIDE Sheets of Daelim Co., Ltd.

Polyimide-Sheets are available at 304.8 x304.8mm width and length and with minimum thickness of 12.7mm up to maximum thickness of 62mm