Innovation for defence, aerospace and commercial vehicles

High Performance Polymers (HPPs) are the focus of innovation as they offer decisive advantages in various industries, including defence, aerospace, commercial vehicles and electronics. In addition to weight savings through metal replacement, functional benefits should also be considered.

PEEK (polyether ether ketone) is a versatile high performance polymer with excellent mouldability, corrosion resistance and high specific strength.

Our wide range of compounds offers products with continuous service temperatures in excess of 300°C and excellent flammability (UL94 V0). PEEK is well known in the aerospace industry. It optimises the weight and durability of components such as thrust washers, seal rings, insulation and structural parts. In addition, recycled PEEK (R-PEEK) is offered as a costeffective and environmentally friendly alternative to virgin material and shows exceptional versatility in 3D printing.

Another outstanding material: Celazole® PBI. With a glass transition temperature of 427°C, exceptional chemical resistance and excellent dimensional stability, it is ideal for critical aerospace applications. Celazole® PBI is used at high temperatures, making it an excellent candidate for aerospace applications. It retains its full tensile strength after being immersed in hydraulic fluid at 200°F (93°C) for 30 days. It also replaces metal components, resulting in significant weight savings and reduced fuel costs. Celazole® U-60 is specifically designed for military applications such as nose tips, leading edges and ablative heat shields.

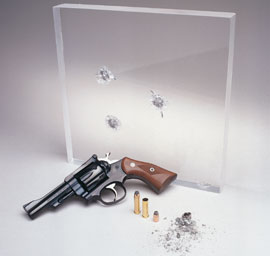

Spartech's acrylic sheet, especially multi-layer sheet, is bullet-resistant and is used for combat helicopter windows, exterior windshield laminates and instrument panels for general aviation and military aircraft. Spartech LLC's Polycast® sheets offer optical clarity, abrasion resistance and durability. Available in a range of colours and sizes, they already meet the stringent requirements of US defence applications.

Royalite® flame-retardant thermoformed sheet from Spartech® LLC (USA) offers flexible, low-volume applications such as structural panels, appliance housings, handgun holsters, transport vehicle interiors and protective systems. The materials meet the highest fire, smoke and toxicity standards, including FAR for aviation, ASTM-E84 for construction and MBSS302 for transportation. Different colours, textures and even soft-touch surfaces are available and can be produced in a single production step. A global sourcing network spanning North America, Europe and Asia ensures that the best materials and technologies are available to meet specific requirements. These international partnerships foster innovation and optimise supply chains to efficiently meet the needs of the defence sector.

The BIEGLO Group offers its range of special HPP products to its global customers via the generic web shops www.PEEK-shop.com, www.POLYIMIDE-shop.com, www.PAI-shop.com, www.PBI-shop.com and www.bieglo.com

BARplast LLC is the Taxas-subsidiary of the BIEGLO Group from Germany. BARplast distributes POLYIMIDEs such as Aurum™ TPI, various thermoset PIs such as PLAVIS, PEEK and R-PEEK. www.BARplast.com

For further information, please contact BIEGLO GmbH info@bieglo.com in Europe or info@barplast.com for US projects.