Quality characteristics

The unique performance of polyamide-imide (PAI) is the result of converting a thermoplastic into a cross-linked thermoset during a longer curing process. This then has a long-term service temperature of 260 ° C and can also be far into the kyogene range resistant. Torlon is characterized by high impact resistance, exceptional mechanical strength and very good retention of these properties at high temperatures.

Applications

PAI products (PAI Rod) are suitable for many applications such as gears, rollers, plasma chamber hardware, and contact holders. In addition, Torlon can be processed into chip holders and sockets, sliding strips in aerospace, insulation bodies in electrical engineering, slide bushings in hydraulic systems, and sipes in compressors.

We offer

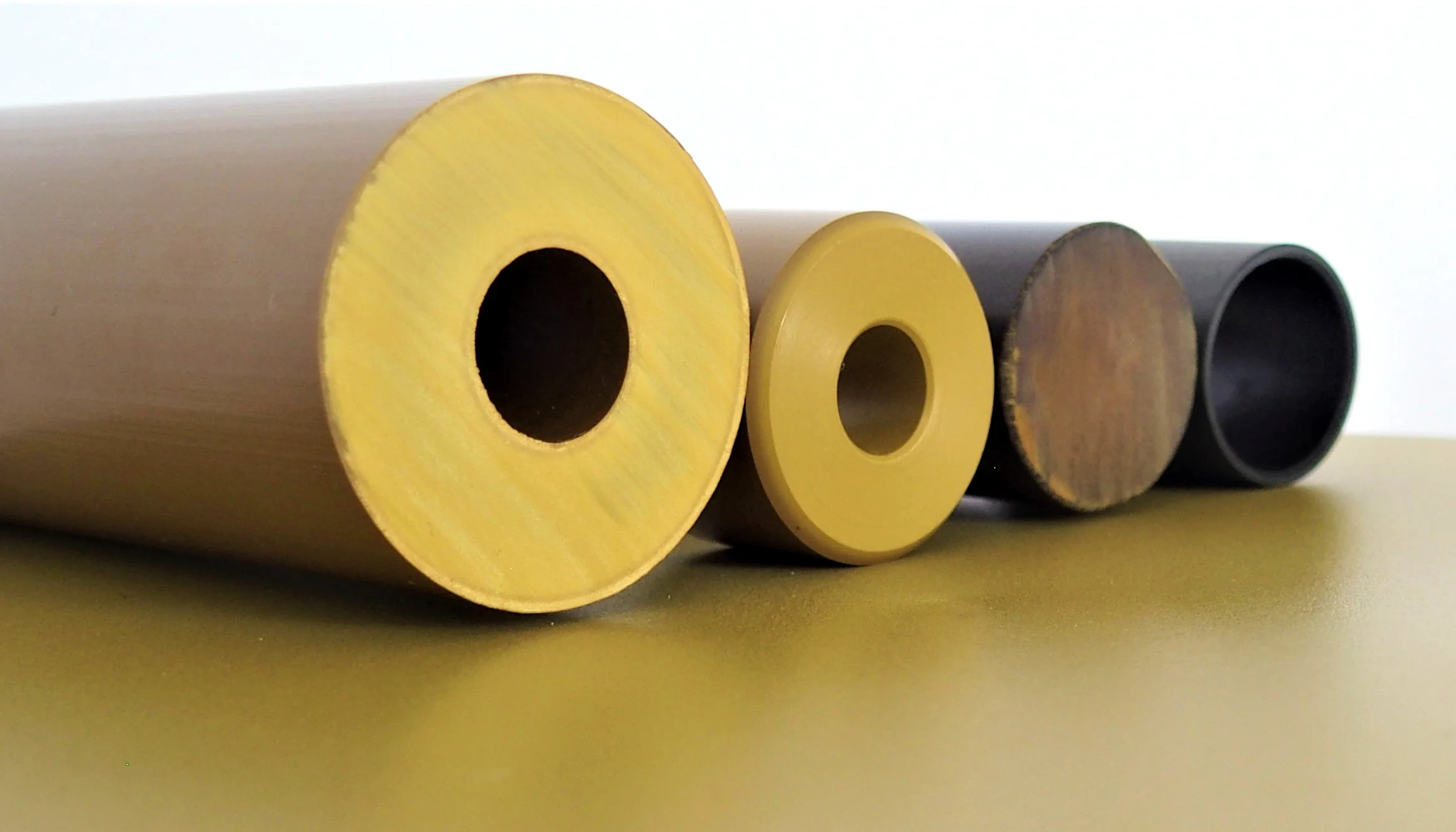

BIEGLO offers PAI-Rods of different PAI types, Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF), with each type being most suitable for a particular application. PAI-rods can be extruded up to a thickness of 15.9 cm, after which rods must be hot-compression molded.